Pottery, an age-old craft, has enchanted humanity for millennia.

Potters, the magicians behind this art, transform raw clay into stunning ceramics using a blend of traditional techniques and modern innovations.

Creating ceramic objects involves not only shaping the clay but also ensuring safety by using protective gear and premixed, wet clay bodies to avoid inhaling clay dust.

Join us as we unravel the secrets of pottery making, from the types of clay and essential tools to the diverse methods that bring these beautiful creations to life.

Key Takeaways:

- Potters create ceramics using various types of clay and techniques.

- The pottery making process involves multiple stages, including shaping, drying, and firing.

- Modern technology and traditional methods both play crucial roles in the creation of ceramic objects.

The Role of Potters in Creating Ceramics

Potters are the heart and soul of the ceramic world.

They transform raw clay into beautiful and functional objects through a series of carefully executed steps.

From selecting the right type of clay to mastering various pottery techniques, potters play a crucial role in the creation of ceramics.

Types of Clay Used in Pottery

Pottery is a mesmerizing blend of art and science, and the type of clay used plays a pivotal role in the final creation.

From the delicate allure of porcelain to the robust charm of stoneware, and the earthy appeal of earthenware, each type of clay brings its own unique qualities to the potter's wheel.

Let's dive into the fascinating world of pottery clay and uncover what makes each type so special.

Porcelain Clay

Porcelain clay is known for its fine texture and high firing temperatures. It is often used to create delicate and translucent ceramics, such as fine china and decorative items. Porcelain clay requires careful handling and precise firing to achieve its characteristic smooth and glass-like surface.

Stoneware Clay

Stoneware clay is a versatile and durable material that is commonly used for making functional pottery items, such as plates, bowls, and mugs. It is fired at high temperatures, resulting in a non-porous and heat-resistant finish. Stoneware clay is popular among both studio potters and hobbyists.

Earthenware Clay

Earthenware clay is a low-fire clay that is often used for creating decorative pottery and flower pots. It is more porous than stoneware and porcelain, making it less suitable for functional items that need to hold liquids. However, earthenware clay is easy to work with and is ideal for beginners.

The Pottery Making Process

Making pottery is a journey of transformation, where raw clay evolves into beautiful, functional art.

From the initial preparation to the final drying stage, each step in the pottery making process is a testament to skill and creativity.

Let’s explore the intricate steps that bring a lump of clay to life, revealing the magic behind every handcrafted piece.

Preparing the Clay

The first step in the pottery making process is preparing the clay. This involves wedging the clay to remove air bubbles and ensure a consistent texture. Potters may also add other minerals or organic matter to the clay body to achieve specific properties.

Shaping the Clay

Once the clay is prepared, potters use various techniques to shape it into the desired form. Wheel throwing, hand building, and slip casting are some of the most common methods used to create pottery. Each technique requires a different set of skills and pottery tools.

Drying the Clay

After shaping, the clay must be dried to a leather-hard state before it can be further refined. This stage is crucial as it allows the clay to firm up, making it easier to handle and decorate. Drying times can vary depending on the type of clay and the size of the piece.

Pottery Techniques

Pottery is an ancient art form that offers endless possibilities for creativity and expression.

From the rhythmic spinning of the wheel to the meticulous hand-building and precise slip casting, each technique brings its own unique charm and challenges.

Pottery techniques have evolved over thousands of years.

Today, potters combine traditional techniques with modern technology to create innovative and unique ceramic pieces.

Wheel Throwing

Wheel throwing is a popular technique used by potters to create symmetrical and round pottery items. The potter's wheel spins the clay while the potter shapes it using their hands and basic tools. This method requires a high level of skill and practice to master.

Hand Building

Hand-building is a versatile technique that allows potters to create a wide range of shapes and forms without the use of a potter's wheel. Techniques such as coiling, pinching, and slab building are commonly used in hand building. This method is ideal for creating unique and intricate designs.

Slip Casting

Slip casting involves pouring liquid clay, known as slip, into plaster molds. The plaster absorbs the moisture from the slip, leaving a thin layer of clay on the mold's surface. Once the clay has dried to a leather-hard state, the mold is removed, and the piece is refined and fired.

Decorating Pottery

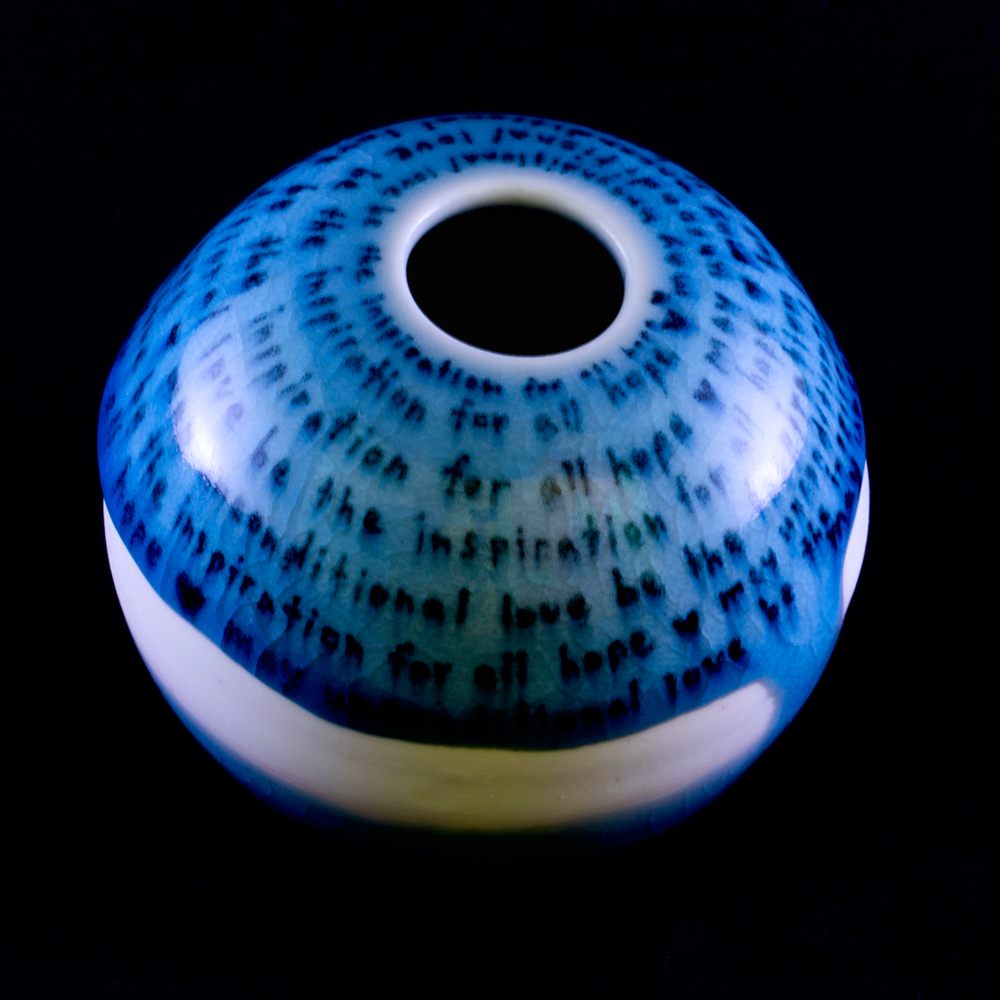

Glazing pottery is where functionality meets artistry, turning simple clay pieces into stunning works of art.

From the vibrant hues of glazing to the intricate details of added decorative elements, each technique offers a unique way to personalize and elevate your pottery.

Glazing is a crucial step in the pottery making process that adds color, texture, and a protective layer to the ceramic piece.

Potters apply glaze using various techniques, such as brushing, dipping, and spraying.

The glaze firing process then melts the ceramic glaze, creating a smooth and glass-like surface.

Potters often add decorative elements to their pottery to enhance its aesthetic appeal.

Techniques such as carving, stamping, and applying slip or underglaze designs are commonly used.

Some potters also incorporate mixed media, such as gold leaf or other materials, to create unique and eye-catching pieces.

Firing the Pottery

Firing pottery is the transformative journey that turns raw clay into resilient, beautiful ceramics by first getting it bisque fired.

Firing temperatures play a crucial role in the pottery making process.

Different types of clay and glazes require specific firing temperatures to achieve the desired results.

For example, porcelain clay requires higher firing temperatures than earthenware clay.

This process involves two critical stages: bisque firing and glaze firing.

Each step plays a vital role in ensuring your pottery is not only visually stunning but also durable and functional.

Understanding the appropriate firing range is essential for creating durable and high-quality ceramics.

Bisque Firing

Bisque firing is the first firing process that transforms the dried clay into a durable and porous bisque ware. This initial firing removes any remaining moisture and organic matter from the clay, making it ready for glazing. Bisque firing temperatures typically range from 1730°F to 1940°F.

Glaze Firing

Glaze firing is the second firing process that melts the applied glaze, creating a smooth and glass-like surface. The firing temperatures for glaze firing can vary depending on the type of clay and glaze used. This process also strengthens the ceramic piece, making it more durable and functional.

Tools and Equipment Used in Pottery

Creating beautiful pottery requires more than just skill; it demands the right tools and equipment.

From the pottery wheel to the kiln, each piece of equipment plays a crucial role in shaping and firing your clay masterpieces.

Pottery Wheels

Pottery wheels are essential tools for wheel throwing. They come in various types, including electric and kick wheels. Potters use the wheel to shape the clay into symmetrical forms, such as bowls, vases, and plates.

Kilns

Kilns are used to fire pottery at high temperatures. There are different types of kilns, including electric, gas, and wood-fired kilns. Each type of kiln offers unique advantages and firing ranges, allowing potters to achieve specific results.

Basic Tools

Potters use a variety of basic tools to shape, refine, and decorate their pottery. These tools include rib tools, needle tools, wire cutters, and sponges. Each tool serves a specific purpose and helps potters achieve precise and detailed results.

Role of Modern Technology in Pottery

Modern technology has revolutionized the pottery making process.

Electric kilns, digital temperature controllers, and advanced glazing techniques have made it easier for potters to achieve consistent and precise results.

Additionally, 3D printing and other innovative technologies have opened up new possibilities for creating intricate and complex ceramic designs.

Art of Pottery at Home

Pottery making is not limited to professional studios.

Many hobbyists and enthusiasts enjoy creating pottery at home.

With the right tools and materials, anyone can explore the art of pottery and create their own unique ceramic pieces.

Home pottery studios often include a potter's wheel, a small kiln, and basic tools.

Significance of Pottery in Fine Art

Pottery is not just a craft; it is also a form of fine art.

Many ceramic artists create pieces that are displayed in galleries and museums around the world.

These artists push the boundaries of traditional pottery techniques, experimenting with new forms, materials, and concepts.

Role of Pottery Studios

Pottery studios provide a space for potters to create, experiment, and refine their craft.

These pottery studios are equipped with the necessary tools and equipment, such as pottery wheels, kilns, and basic tools.

Many studios also offer classes and workshops, allowing aspiring potters to learn and develop their skills.

Importance of Removing Air Bubbles

Removing air bubbles from the clay is essential to prevent defects and cracks during the firing process.

Potters use a technique called wedging to knead the clay and remove any trapped air.

This process ensures a consistent texture and reduces the risk of air pockets that can cause the pottery to explode in the kiln.

Impact of Glaze Firing on Pottery

Glaze firing is a critical step in the pottery making process.

It not only adds color and texture to the ceramic piece but also strengthens it.

The glaze firing process involves heating the pottery to high temperatures, causing the glaze to melt and form a smooth, glass-like surface.

This process enhances the durability and functionality of the pottery.

Use of Plaster Molds in Pottery

Plaster molds are commonly used in slip casting to create consistent and detailed ceramic pieces.

The plaster absorbs moisture from the liquid clay, leaving a thin layer of clay on the mold's surface.

Once the clay has dried to a leather-hard state, the mold is removed, and the piece is refined and fired.

Role of Raw Materials in Pottery

Raw materials, such as clay, minerals, and organic matter, play a crucial role in the pottery making process.

Different types of clay have unique properties that affect the final outcome of the ceramic piece.

Potters carefully select and prepare their raw materials to achieve specific results.

Use of Mixed Media in Pottery

Many ceramic artists incorporate mixed media into their pottery to create unique and innovative designs.

Materials such as gold leaf, glass, and metal can be combined with clay to add texture, color, and visual interest.

This approach allows artists to push the boundaries of traditional pottery techniques.

Importance of Temperature Control in Kilns

Temperature control is crucial in the firing process.

Kilns must be heated to specific temperatures to achieve the desired results.

Digital temperature controllers and pyrometers help potters monitor and regulate the firing temperatures, ensuring consistent and precise outcomes.

Role of Pottery in Creating Functional Items

Pottery is not just an art form; it also serves a practical purpose.

Many potters create functional items, such as plates, bowls, and mugs, that are used in everyday life.

These items are designed to be durable, heat-resistant, and aesthetically pleasing.

Use of Slab Rollers in Pottery

Slab rollers are tools used to create flat and even slabs of clay.

These slabs can be used in hand-building techniques to create a variety of shapes and forms.

Slab rollers help potters achieve consistent thickness and reduce the time and effort required to prepare the clay.

Role of Pottery in Sculpture

Pottery is not limited to functional items; it is also used in sculpture.

Many ceramic artists create intricate and detailed sculptures using various pottery techniques.

These sculptures can range from small figurines to large installations, showcasing the versatility and creativity of pottery.

Use of Iron Oxide in Glazing

Iron oxide is a common ingredient in glazes that adds color and texture to the ceramic piece.

It can produce a range of colors, from earthy browns to vibrant reds and oranges.

Potters carefully control the amount and application of iron oxide to achieve the desired effects.

Importance of High Temperatures in Firing

High temperatures are essential in the firing process to transform raw clay into durable and functional ceramics.

Different types of clay and glazes require specific firing temperatures to achieve the desired results.

Understanding and controlling these temperatures is crucial for successful pottery making.

Use of Electric Kilns in Pottery

Electric kilns are widely used in pottery studios for their convenience and precise temperature control.

They are easy to operate and maintain, making them ideal for both professional and home studios.

Electric kilns offer a consistent and reliable firing process, ensuring high-quality results.

Use of Ball Clay in Pottery

Ball clay is a fine-grained clay that is often used in pottery to improve plasticity and workability.

It is commonly added to other clays to enhance their properties and achieve specific results.

Ball clay is an essential ingredient in many pottery recipes.

Timeless Beauty: Art and Science of Pottery

Pottery is a mesmerizing blend of art and science, where skilled artisans transform raw clay into stunning ceramics.

Using a variety of clays and techniques, potters shape, dry, and fire their creations, blending modern technology with traditional methods.

This intricate process results in both functional and artistic pieces, showcasing the limitless creativity and innovation within the world of ceramics.

Whether you're a seasoned potter or an admirer of fine art, the journey of pottery making is a testament to human ingenuity and artistic expression.

Ceramics FAQs

Welcome to the FAQs, your go-to guide for all things pottery!

Whether you're a seasoned potter or just starting out, this section is designed to answer your burning questions about the fascinating world of ceramics.

From the types of clay used to the intricate decoration techniques, we've got you covered.

Dive in and discover the secrets behind creating beautiful, durable ceramic pieces that stand the test of time.

Let's get started!

What types of clay do potters use?

Potters use various types of clay, including porcelain clay, stoneware clay, and earthenware clay. Each type of clay has unique properties that affect the final outcome of the ceramic piece.

What is the purpose of bisque firing?

Bisque firing is the first firing process that transforms dried clay into durable and porous bisque ware. This initial firing removes any remaining moisture and organic matter from the clay, making it ready for glazing.

How do potters decorate their pottery?

Potters use various techniques to decorate their pottery, including glazing, carving, stamping, and applying slip or underglaze designs. Some potters also incorporate mixed media, such as gold leaf or other materials, to create unique and eye-catching pieces.

What tools do potters need to get started?

Potters need a variety of tools to get started, including a pottery wheel, kiln, clay, and basic hand tools like rib tools, wire cutters, and sponges. These tools help shape, trim, and refine the clay into beautiful ceramic pieces.

What is the difference between hand-building and wheel-throwing?

Hand-building involves creating pottery using hands and simple tools, allowing for more organic and unique shapes. Wheel-throwing, on the other hand, uses a pottery wheel to create symmetrical and precise forms. Both techniques offer different creative possibilities and can be combined for diverse results.

How long does it take to fire ceramics?

The firing process can vary depending on the type of clay and kiln used. Typically, bisque firing takes about 8-10 hours, followed by a cooling period of 12-24 hours. Glaze firing can take an additional 8-12 hours, with a similar cooling period.

What are some common glazing techniques?

Common glazing techniques include dipping, brushing, pouring, and spraying. Each method offers different effects and finishes, from smooth and glossy to textured and matte. Experimenting with different techniques can help potters achieve their desired look.

How do you prevent cracks in pottery?

To prevent cracks, it's essential to ensure even drying and firing. Potters should avoid rapid temperature changes and ensure that the clay is uniformly thick. Proper wedging and compressing the clay can also help eliminate air bubbles that may cause cracks.

What is the significance of wedging clay?

Wedging is the process of kneading the clay to remove air bubbles and ensure a consistent texture. This step is crucial for preventing cracks and ensuring the clay is easy to work with. Properly wedged clay results in stronger and more durable ceramic pieces.

Yearning to make your own pottery? Check out Andy Ward's Ancient Pottery's video!

Want even more content about creativity and art?

Be sure to check out all of our creative chronicles!

Love pottery and working with clay?

Check out some of our other ceramic articles:

-What is the difference between ceramics and pottery?

-Is stoneware the same as ceramic?

-What are the four types of pottery?

-What are the 5 methods of working with clay?

-What is the difference between hand building and throwing clay?