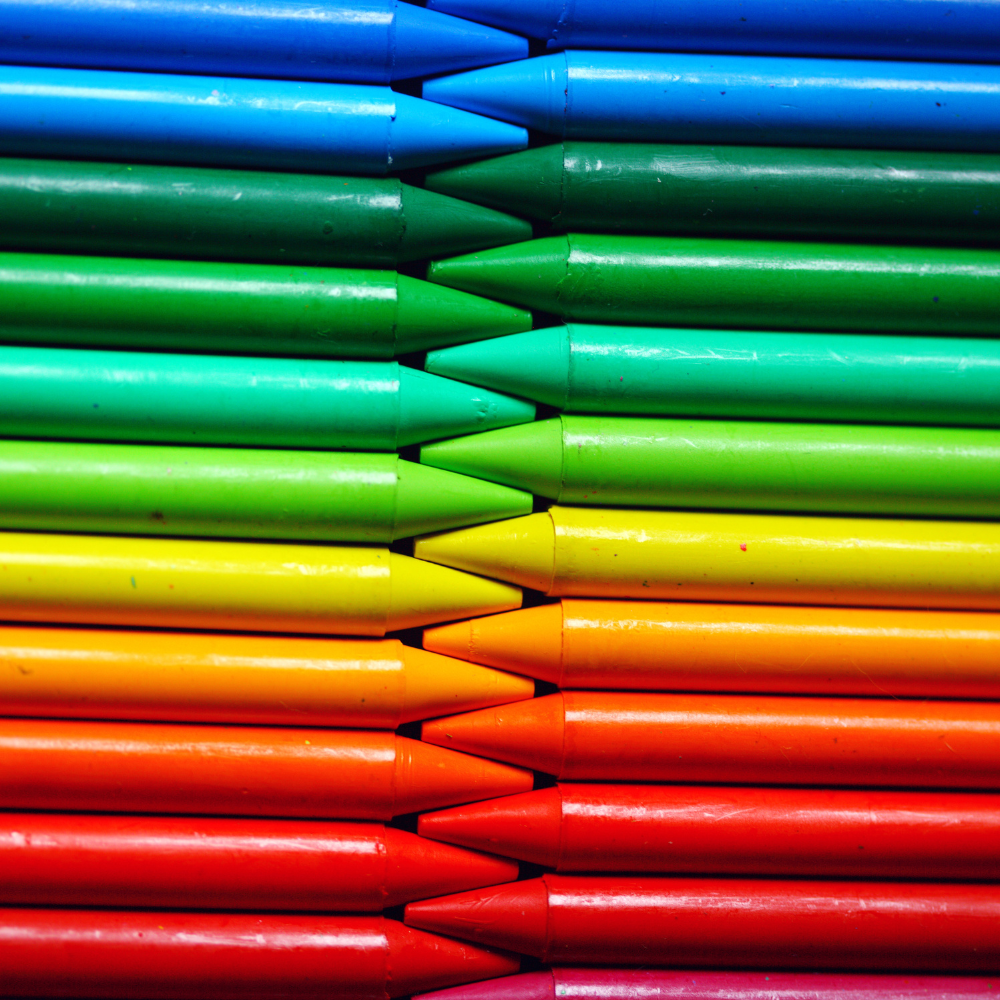

Crayons aren't just sticks of color; they're tiny marvels of engineering.

Ever wondered what gives crayons their vibrant hues and smooth texture?

Crayons, a staple in classrooms and children's art supplies, are more complex than they appear.

This article peels back the wrapper on the humble crayon, zooming in on the enigmatic "secret powder" that's key to their creation.

Understanding what goes into making crayons not only enlightens consumers but also highlights the advancements and safety measures implemented by crayon manufacturers.

Dive into the fascinating world of crayon composition, where science meets art, ensuring every scribble is safe and spectacular.

Key Takeaways:

- Understanding Ingredients: Learn about the basic ingredients contained in crayons, focusing on the role of the "secret powder" that defines their quality and usability.

- Health and Safety: Insight into the health concerns historically associated with crayons, such as asbestos contamination, and the measures taken to ensure safety.

- Innovations in Crayon Manufacturing: Explore how modern technologies and environmental considerations are shaping the future of crayon production.

Basic Composition of Crayons

Crayons are primarily composed of paraffin wax and color pigments.

Paraffin wax, derived from fossil fuels, is favored for its ease of melting and solidifying, making it ideal for the crayon making process.

The wax acts as a binder for the powdered pigment, which is responsible for the crayon's color.

The term "secret powder" often refers to the specific blend of powdered pigments and other materials that give crayons their unique colors and properties.

These pigments are carefully selected and mixed to achieve a wide range of Crayola crayon colors.

The precision in this process ensures that each crayon delivers consistent color quality.

Historical Context and Safety Concerns

In the past, concerns were raised about the safety of crayons when reports surfaced about asbestos contamination.

Asbestos fibers, once commonly used in various industries for their resistance to heat and corrosion, were reportedly found in some crayon products.

This led to widespread fear of asbestos exposure, particularly worrying given crayons' target audience—children.

Following these reports, crayon manufacturers, including major brands like Crayola and Rose Art, conducted thorough investigations.

Studies by the Environmental Protection Agency and organizations like the Scientific Analytical Institute found that newer crayons did not contain these harmful fibers, reassuring the public about the safety of these art materials.

Advances in Crayon Ingredients

Modern crayon production has seen a shift towards more eco-friendly and safe materials.

Carnauba wax, known for its higher melting point, has been increasingly used as an alternative to paraffin wax.

This natural wax, derived from the leaves of the carnauba palm, is non-toxic and provides a harder, smoother finish.

Additionally, crayon manufacturers now use pre-measured amounts of non-toxic, FDA-approved color pigments.

These advancements not only improve the safety standards of crayons but also enhance their environmental footprint, aligning with the growing demand for sustainable and safe consumer products.

Environmental Impact of Crayon Production

The production of crayons, particularly those involving crayon wax and color pigments, has raised environmental concerns over the years.

The process of melting hot wax, combined with various dyes and chemicals, releases volatile organic compounds (VOCs) into the air, contributing to air pollution and potential health risks.

Companies like Crayola have been at the forefront of addressing these issues by implementing cleaner, more sustainable practices in their manufacturing processes.

This shift not only helps in reducing the environmental footprint but also aligns with the growing consumer demand for eco-friendly products.

Moreover, the disposal of used crayons poses another environmental challenge.

Traditional crayons, made primarily from paraffin wax, do not decompose easily, leading to significant waste in landfills.

The Creative Materials Institute and other organizations have advocated for recycling programs that repurpose used crayons into new products.

This approach not only minimizes waste but also promotes the circular economy concept, turning potential environmental liabilities into creative opportunities.

These initiatives underscore the importance of sustainability in the widespread use of everyday creative materials like crayons.

Environmental Considerations in Ingredients

The quest for eco-friendly materials in manufacturing is pivotal, and crayons are no exception.

Recent shifts towards sustainable practices have led manufacturers to explore alternatives to traditional components that may harm the environment.

For instance, the inclusion of non-toxic, biodegradable color pigments is becoming more prevalent.

These pigments are derived from natural sources such as fruits, vegetables, and minerals, which not only reduce the ecological footprint but also ensure safety for young users.

Moreover, the reduction of harmful substances like talc, which was once a common filler in many crayons, highlights the industry's commitment to environmental health.

Talc, often mined, can have detrimental effects on local ecosystems.

Replacing talc with eco-friendly alternatives such as chalk not only diminishes the environmental impact but also enhances the product's safety profile.

This shift is crucial as it aligns with global efforts to promote sustainability in product manufacturing, ensuring that the crayons are both safe for use and kinder to the planet.

Impact of Color Pigments on Crayon Quality

Color pigments are crucial in determining the vibrancy and appeal of crayons.

These pigments, often derived from both natural sources and synthetic methods, are carefully selected to ensure that each crayon delivers consistent color quality.

Manufacturers like Crayola ensure that these pigments are non-toxic, adhering to rigorous safety standards.

The choice of pigment not only affects the safety of the crayon but also its marketability, as vibrant and consistent colors are more appealing to consumers, particularly in educational and artistic settings.

The process of integrating color pigments involves pre-measured amounts to maintain uniformity across batches.

This precision ensures that one crayon in a box has the same shade and intensity as another.

The challenge lies in balancing the quality of color with environmental and health considerations.

Advances in technology have led to the development of eco-friendly pigments that reduce environmental impact without compromising color quality.

These innovations reflect a growing consumer demand for products that are both high in quality and sustainability.

Significance of Measurements in Production

The precision in crayon manufacturing is crucial, especially when it comes to the integration of pre-measured amounts of ingredients.

This meticulous approach ensures consistency in texture, melting point, and color output across batches.

For instance, the exact quantity of color pigments and waxes mixed together determines the vibrancy and uniformity of the crayons.

This precision not only enhances the product quality but also significantly reduces waste during production, aligning with eco-friendly manufacturing practices.

Moreover, the use of pre-measured amounts is essential in maintaining the non-toxic standard of crayons, particularly in crayon brands like Crayola.

By carefully measuring components such as color pigments and binding agents, manufacturers can avoid the accidental inclusion of harmful substances.

This methodical precision ensures that products meet stringent safety standards, thereby safeguarding children's health while they unleash their creativity through coloring.

Impact of Regulatory Changes on Formulations

The evolution of crayon formulations has been significantly influenced by regulatory changes aimed at enhancing product safety and environmental sustainability.

As governments worldwide tighten regulations on chemical use, crayon manufacturers have been prompted to innovate and adapt.

This shift is particularly evident in the reduction of toxic substances traditionally used in crayons, such as certain color pigments and binding agents.

The move towards non-toxic, eco-friendly components not only aligns with global safety standards but also caters to the growing consumer demand for safer products for children.

Moreover, these regulatory changes have spurred crayon manufacturers to explore and adopt alternative materials that maintain the quality and vibrancy of crayons while ensuring safety.

For instance, the replacement of certain synthetic dyes with natural color pigments has been a direct response to these new standards.

This adaptation not only affects the composition of the crayons but also impacts the manufacturing processes, pushing companies towards more sustainable practices.

As a result, the industry is witnessing a significant transformation in how crayons are produced, driven by the dual forces of regulation and consumer preference.

Role of Binders in Crayon Durability

The durability and consistency of crayons are significantly influenced by the binders used in their composition.

Binders are crucial because they hold the color pigment and wax together, preventing the crayon from crumbling during use.

Common binders in crayon manufacturing include paraffin wax and beeswax, both known for their non-toxic properties and ability to adhere color pigments effectively.

These substances ensure that crayons can withstand pressure during drawing, enhancing the user experience by providing a smooth, even application of color.

Moreover, advancements in binder technology are continually being explored to improve crayon quality.

Researchers are investigating eco-friendly and sustainable binders that do not compromise the crayon's performance.

For instance, the use of soybean wax and other natural oils are being tested as alternatives to the traditional petroleum-based waxes.

These innovations aim to maintain the crayon's functionality while ensuring safety and environmental responsibility.

The exploration of these new binders reflects the industry's commitment to enhancing crayon longevity and performance, aligning with consumer demands for durable and eco-friendly products.

Impact of Global Supply Chains on Production

Global supply chains play a pivotal role in the production of crayons, particularly in the sourcing of raw materials such as wax, talc, and color pigments.

The efficiency and sustainability of these supply chains directly affect the quality and cost of the final product.

For instance, crayola crayons, renowned for their vibrant colors and quality, rely on well-established supply networks to procure high-grade pigments and other essential materials.

These networks must also adhere to strict quality control standards to ensure that the crayons are non-toxic and safe for children.

Furthermore, the globalization of crayon production has prompted manufacturers to adopt more robust logistics and supply chain strategies.

This includes the use of pre-measured amounts of raw materials to reduce waste and increase efficiency during production.

By optimizing these processes, crayon manufacturers can not only enhance product quality but also minimize their environmental impact.

This strategic approach to supply chain management is crucial for maintaining the balance between high-quality crayon production and environmental sustainability, ensuring that the art supplies industry remains both innovative and responsible.

Enhancing Crayon Longevity and Performance

In the quest to improve the durability and performance of crayons, manufacturers are increasingly turning to advanced coating technologies.

These innovations are designed to enhance the crayon's resistance to breaking and to provide a smoother, more consistent color application.

By integrating a specialized coating, crayons can achieve a higher level of performance that appeals to both young artists and professional users.

This not only improves the user experience but also extends the life of the crayon, which contributes to reduced waste and supports eco-friendly initiatives.

The development of these coatings often involves the use of pre-measured amounts of additives that enhance the crayon's properties without compromising safety.

These additives are meticulously tested to ensure they meet strict non-toxic standards before being integrated into the crayon production process.

The precise formulation helps in maintaining the balance between performance enhancement and safety, ensuring that the crayons remain safe for use by children.

This focus on advanced materials and technologies underscores the industry's commitment to innovation and quality in crafting tools for artistic expression.

Non-toxic Alternatives in Crayon Composition

In recent years, the shift towards non-toxic and eco-friendly crayon compositions has gained significant momentum.

Manufacturers are increasingly exploring alternatives to traditional ingredients that pose health risks, such as the previously found asbestos in some crayons.

For example, soybean oil and beeswax are being used as sustainable and safe alternatives to paraffin wax, which is derived from petroleum and has raised environmental concerns.

This transition not only reflects a commitment to consumer safety but also impacts the environmental footprint of crayon production.

By adopting biodegradable and renewable materials, companies are reducing their reliance on fossil fuels and minimizing waste.

These changes in crayon composition are not just beneficial for the environment but also enhance the market appeal of crayons as safe, non-toxic options for parents and educators concerned about the materials in children's products.

Discovering Historical Crayon Composition

The discovery of asbestos in crayons has been a significant concern in the industry.

Historically, some crayon manufacturers inadvertently included asbestos-contaminated talc in their products.

Asbestos, a known carcinogen, raised serious health concerns which led to major reforms in crayon manufacturing processes.

This issue highlighted the importance of stringent quality control and the need for thorough testing of all raw materials used in crayon production to ensure they are safe and non-toxic.

In response to these concerns, crayon manufacturers have revamped their sourcing strategies, opting for certified asbestos-free talc and other safer alternatives.

These changes not only ensure the safety of the children using crayons but also enhance the trust and reliability of brands like Crayola in the market.

The shift towards safer, non-toxic materials is part of a broader move towards sustainability and responsibility in the crayon industry, aligning with global standards for health and safety in consumer products.

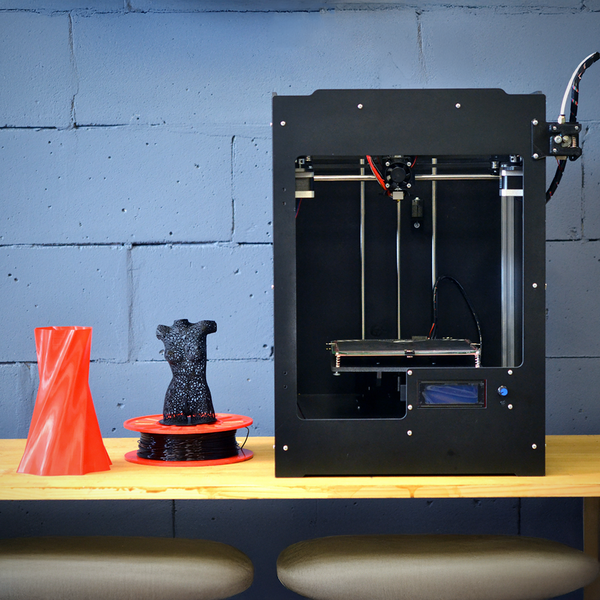

Technological Advancements in Manufacturing

In the realm of crayon production, technological advancements have significantly optimized both the quality and safety of the final products.

Modern manufacturing processes now employ advanced machinery that ensures pre-measured amounts of each ingredient are used.

This precision helps in maintaining consistency in crayon quality and in preventing any accidental inclusion of harmful substances like asbestos, which was found in some crayons in the past due to cross-contamination in factories.

Additionally, the use of automation in the crayon manufacturing process has not only increased production efficiency but also reduced the likelihood of human error.

Machines equipped with sensors can detect inconsistencies in the mixture or spot any foreign materials that do not belong in the crayon.

This level of control is crucial in ensuring that every box of crayons, from the first box to the last, adheres to stringent health and safety standards, thereby guaranteeing a safe and enjoyable experience for end-users.

Health and Safety Standards in Manufacturing

In recent years, safety concerns have emerged regarding the presence of asbestos in crayons, a serious issue given the latency period of asbestos-related diseases.

Reports have surfaced that some crayons tested positive for asbestos, a known carcinogen, prompting a reevaluation of safety protocols in crayon production.

Manufacturers are now mandated to use pre-measured amounts of non-toxic materials to ensure that the final products are safe for children.

This includes rigorous testing and certification by safety standards organizations to guarantee that crayons are free from harmful chemicals.

Furthermore, the shift towards non-toxic and safe materials in crayons is not just a health imperative but also makes sense from a consumer trust perspective.

Parents and educators are increasingly vigilant about the safety of the materials children use, which has pressured manufacturers to adopt stricter safety measures.

By ensuring that products like crayons, markers, and colored pencils meet high safety standards, companies can maintain consumer trust and ensure the continued widespread use of these creative tools in educational and artistic settings.

This commitment to safety is crucial in sustaining the market for these beloved creative instruments.

Role of Talc in Crayons

Talc deposits, another component often found in crayons, play a significant role in achieving the desired texture and consistency.

Talc, a mineral primarily used in cosmetics and paper, helps in the smooth application of color and prevents crayons from feeling waxy or greasy.

Despite its benefits, the use of talc has been scrutinized due to health concerns in other industries, particularly in cosmetics.

Crayon manufacturers have addressed these concerns by ensuring that the talc used in crayons is free of asbestos and adheres to strict quality control standards.

Manufacturing Process: From Wax to Crayon

The crayon manufacturing process begins with melting the wax base, into which the powdered pigment and other materials like talc and carnauba wax are mixed.

This mixture is then poured into molding machines, where it takes the shape of a crayon.

Once cooled, the crayons are removed from the molds and subjected to quality checks.

Rejected crayons and leftover materials are often recycled within the factory, melted down, and reformed into new crayons.

This not only minimizes waste but also ensures that all the crayons meet the company's quality standards before they reach consumers.

Innovations in Crayon Production

Innovation in crayon production is not just about safety and efficiency; it's also about expanding the possibilities of artistic expression.

Special effects crayons, which include glitter and multicolored options, are a result of continuous experimentation with different materials and pigments.

These innovations are driven by both artistic and environmental motivations.

For instance, crayon manufacturers are exploring the use of beeswax and soy waxes as sustainable alternatives to paraffin wax.

These natural waxes cater to the growing market for eco-friendly art supplies.

Future of Crayons: Sustainability and Artistry

As environmental concerns become more prominent, crayon manufacturers are challenged to find solutions that reduce the ecological impact of their products without compromising quality.

This includes exploring alternative energy sources for crayon factories and reducing reliance on fossil fuels.

Moreover, the future of crayons lies in enhancing their role in artistic expression.

By continuously improving the quality and variety of crayons, manufacturers can support artists of all ages in their creative endeavors, making crayons a tool not just for coloring, but for genuine artistic creation.

Coloring the Future: Bright Evolution of Crayons

Crayons are not just simple tools for children's crayon art but are sophisticated products born from a meticulous blend of science and creativity.

They are a complex blend of science and art, made primarily from paraffin wax and color pigments, with the "secret powder" being the key to their color and quality.

The journey from basic paraffin wax to the inclusion of safer, eco-friendly materials showcases the evolution of crayon manufacturing.

With ongoing innovations aimed at enhancing both safety and environmental sustainability, crayons are set to remain a cherished instrument of artistic expression for generations to come.

This commitment to improvement ensures that every stroke of a crayon is not only a burst of color but a mark of quality and care.

As crayon manufacturers continue to innovate, they ensure that crayons remain a beloved and safe tool for artistic expression across generations.

Crayon FAQs

Welcome to the Crayon FAQs section!

Whether you're a curious parent, an enthusiastic teacher, or just a crayon aficionado, you've got questions, and we've got answers.

From the mysterious ingredients that give crayons their vibrant colors to safety measures and environmental impacts, this section is designed to shed light on all your crayon-related queries.

Dive into our frequently asked questions to learn more about these colorful tools that spark creativity in people of all ages.

What exactly is the "secret powder" in crayons?

The "secret powder" in crayons refers to the specially formulated blend of powdered pigments and other materials that give crayons their distinct colors and properties.

Are crayons safe for children to use?

Yes, modern crayons are made with non-toxic materials and are rigorously tested to meet safety standards, making them safe for children to use.

How are crayon manufacturers addressing environmental concerns?

Crayon manufacturers are increasingly using eco-friendly materials like carnauba wax and exploring sustainable practices in production to reduce environmental impact.

Can crayons be recycled or reused in any way?

Absolutely! While traditional recycling centers might not accept crayons, they can be melted down and reformed into new shapes or even used in various DIY art projects. Some organizations specifically collect used crayons to recycle them into new sets for children's hospitals and schools.

What is the best way to remove crayon marks from walls and furniture?

Crayon marks can usually be removed from walls and furniture with a bit of elbow grease and the right cleaner. For walls, a damp sponge dipped in baking soda does wonders. For furniture, rubbing alcohol can be effective, but always test a small area first to ensure it doesn't damage the finish.

Are there any health risks associated with using crayons?

No, there are no known health risks associated with using crayons as they are typically made from non-toxic materials. However, it's always a good idea to supervise young children to ensure they use crayons as intended and do not ingest them.

How long have crayons been around, and who invented them?

Crayons have been around since the early 20th century. The first mass-produced crayons were made by Binney & Smith, the company now known as Crayola, in 1903. They were designed to be an affordable, safe coloring tool for children.

What are some creative ways to use crayons in art projects?

Crayons can be used in a multitude of creative art projects beyond simple coloring. They can be melted into molds to create custom crayon shapes, used for crayon etching techniques, or even ironed between sheets of wax paper to make colorful stained glass art.

Do crayons expire or go bad?

Crayons do not expire or go bad, but they can break or wear down over time. If crayons are stored in very hot conditions, they may melt, and if they are stored in extremely cold conditions, they might become brittle and snap easily.

Interested in creating your own crayons? Check out HGTV Handmade's video!

Want even more content about creativity and art?

Be sure to check out all of our creative chronicles!

Love crayons and crayon art?

Check out some of our other articles:

-How do you make crayons look professional?

-How do you make easy crayons?

-What is the secret ingredient in crayons?